Surfing Magazine | Surfboard Makers Board Technology Feature

Todd Proctor Interview

Background:

I shaped my first few hundred boards out of a little woodshed in my grandpas backyard because no one else wanted me to “make a mess” trying my hand at shaping. I was 19 years old; and the first four boards I shaped out of that woodshed ended up landing me a job working for an established surfboard factory in Oxnard. That was my first job building boards, and it led to working for other companies that allowed me to do my own thing still on the side.

What I noticed right away was that the best boards came out of ultralight blanks and were glassed super light. They had the best performance and responsiveness; they had the best flex. Light and responsive was one part of it, but the other side of the coin and maybe the most important and most overlooked part was that a lighter lamination allowed the boards to bend and warp under pressure; flexing lengthwise, but also even twisting side to side by the force of the rider in maneuvers, and the force of the wave pushing back at them in those maneuvers…a load up, recoil effect. Pushback, torque, etc…. that’s what made a great shape work even that much better, and give it that little extra something; the special spark that ads the magic of a faster and more critical; more dynamic board that takes you to the places that you dream about and doodle on your notebook about.

I really noticed it early on in my shaping career with a lot of the pro’s boards. After they had ridden them for a few surfs, many times the pro guys would be back straight away with feedback. In the factories of various companies I was carving foam for, it was always exciting to shape up a board, and then hear how it went under the feet of really ripping surfers. And since they were the few people that would get a bunch of boards each year, they could get them glassed up super light like that without having a huge pocket crunch to the wallet. Well, the unfortunate thing was that these same magic boards would have very short lifespans due to the nature of the materials used; they would come back buckled, with a sad faced shredder going, “this was the best board ever!!…how fast can we make another one exactly like it?”So, after about ten years of working for other people handshaping boards, I decided to go it solo; and some of my main goals were to make it possible to duplicate the proven magic boards, and my second goal was to harness the flex characteristics of the ultralight poly’s, but get them to last 3-5 times longer than a stock standard glassed poly board. There’s nothing that lasts forever (except your soul), but I thought it sure would be nice to have a magic board that lasted at least a lot longer.That is when I first began thinking about how the construction of a great board is right up there with the actual shape and design of the board. It seemed sad to always be discovering a shape that worked sick, but having that special something be so short-lived; bittersweet….and it seemed wasteful too. I remember seeing so many boards buckled broken beyond repair straight into the trash.

So, one of the things I did when I embarked on my own mission, was to get outside the surfboard industry itself and see what chemists and engineers and scientists were up to developing in the automotive, aircraft, aerospace, marine and military industries. And so, for about three years I went to polymer and composite trade shows all over the planet, and spoke with those scientists that had spent their lives looking through microscopes and tweaking around with elements on the molecular level. And what I found was that whatever your mind can dream up, these guys can turn into a reality. What is possible with surfboards right now would absolutely astound you. The thing is, stuff costs a lot and that next level has to be ready to be received; welcomed; encouraged by an industry and by surfers that actually want something better….

What’s the tech and why is it better?

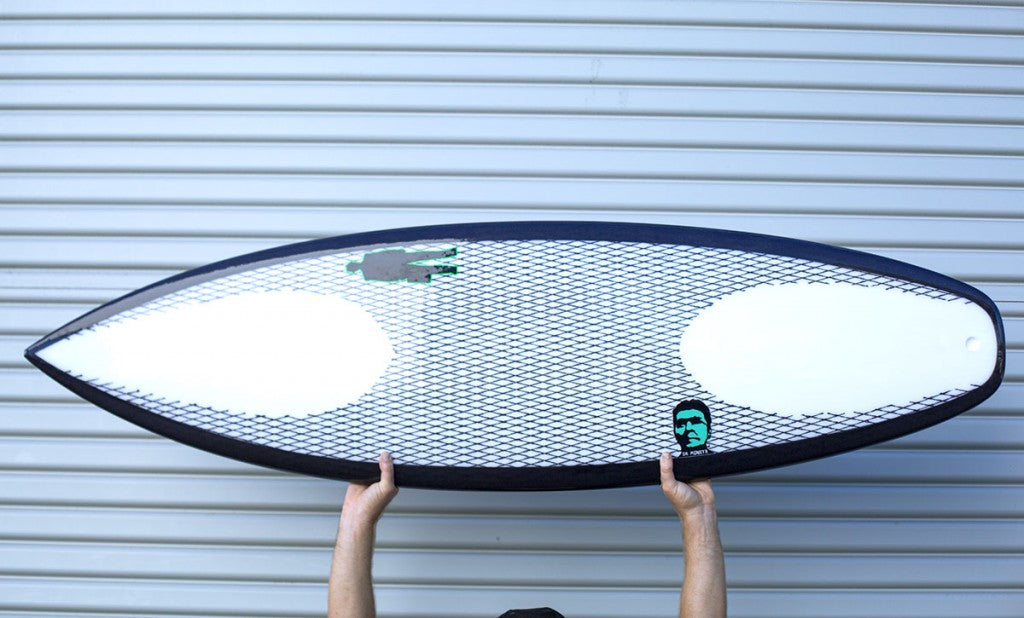

We’ve got a bunch of stuff we are continually working on thanks to having all steps of the process under one roof. This allows us to dream things up and put them directly into process and into the water straight away. The “Titanium II” is a construction that combines polymer engineered stringers, a hybrid epoxy foam core, and a specially woven carbon/ kevlar mesh material….strategically fabricated to engineer specific flex patterns into your favorite shape for more spring and torque out of maneuvers. I feel this is one of the avenues to the future of the kind of high performance surfing we have all been dreaming about.